CASE CX57C Mini Excavator

Request more information:

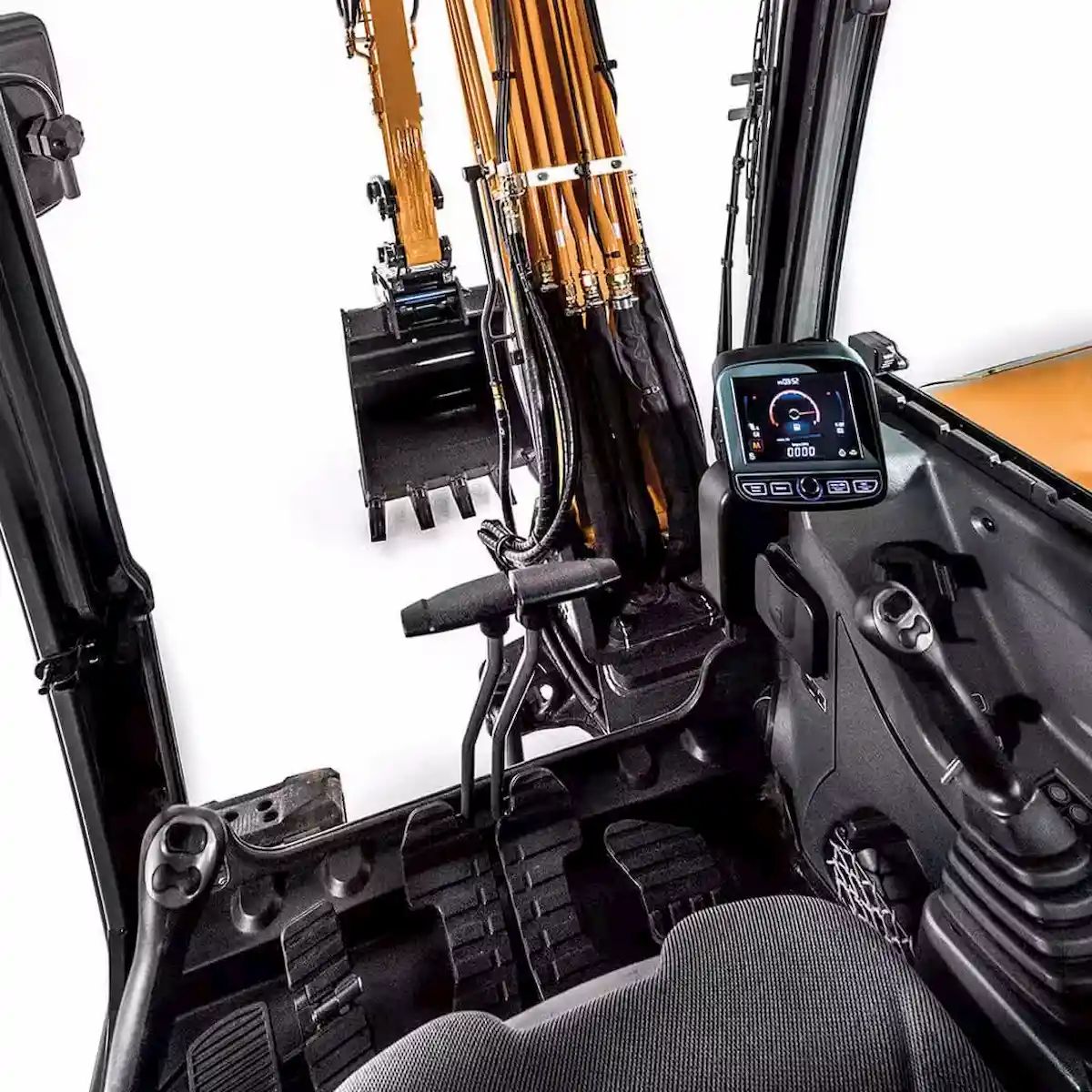

The CASE CX57C Mini Excavator stands out in our diverse construction machinery portfolio. This “large” mini excavator sets the benchmark with its exceptional horsepower, adept at tackling the rigors of substantial excavation tasks. Distinct from its peers in the C Series, the CX57C boasts a traditional tail-swing design complemented by a significant counterweight, ensuring a performance level on par with larger excavators within a compact footprint. It comes with a range of standard performance-enhancing features. These include a deluxe cab equipped with a 7-inch LCD touchscreen monitor, which takes the CX57C to the next level regarding power, versatility, and user-friendly operation.

PDF Brochure: CASE CX57C Mini Excavator Brochure

PDF Specifications: CASE CX57C Mini Excavator Specifications

CASE CX57C Mini Excavator

The CASE CX57C Mini Excavator stands out in our diverse construction machinery portfolio. This “large” mini excavator sets the benchmark with its exceptional horsepower, adept at tackling the rigors of substantial excavation tasks. Distinct from its peers in the C Series, the CX57C boasts a traditional tail-swing design complemented by a significant counterweight, ensuring a performance level on par with larger excavators within a compact footprint. It comes with a range of standard performance-enhancing features. These include a deluxe cab equipped with a 7-inch LCD touchscreen monitor, which takes the CX57C to the next level regarding power, versatility, and user-friendly operation.

CX57C Features

Purpose-Built Productivity:

- Power: Best-in-class 67 hp engine and large counterweight for robust digging forces of 9,550 lbf.

- Lifting Capacity: More than 9,200 lb, ensuring heavy-duty performance.

- Compact Size: Maintains a track width of 6 ft. 4 in. and an operating weight of 12,270 lb.

- Hydraulic Push Blade: Standard feature for efficient backfilling and enhanced stability.

- Auxiliary Hydraulics: Facilitates easy use of thumbs and attachments.

- Automatic 2-Speed Travel: Ensures smooth shifting across diverse terrain types.

- Pattern Selector: Allows easy switching between SAE and ISO control patterns.

- Adjustable Boom: Can be offset left or right for operations in tight spaces or near obstacles.

- Optional Features: Include a long-reach configuration and steel tracks for increased durability and performance in harsh conditions.

Common-Sense Fuel Efficiency:

- Emission Technologies: Combines technologies to meet Tier 4 Final regulations without sacrificing power.

- Two Operating Modes: Helps operators adjust performance according to the task.

- Auto-Idle Function: Reduces fuel consumption by automatically idling the engine during downtime.

CASE Comfort and Visibility:

- Deluxe Cab: This model offers the comfort and features of larger machines, including isolation mounting to minimize noise and vibration.

- Visibility: Floor-to-ceiling glass for superior all-around visibility.

- Amenities: Heat, A/C, Bluetooth radio with USB input and remote, proportional controls, an adjustable heated seat, and a 7″ color touchscreen monitor.

- Touchscreen Monitor: This monitor provides real-time performance data and convenient access to machine functions, with optional rearview camera integration.

Simple Serviceability:

- Easy Access Panels: Two self-locking panels allow access to ground-level service and maintenance points.

- Maintenance Points: Include checkpoints, fill ports, grease points, filters, and more for straightforward and efficient upkeep.

CX57C Standard Equipment

ENGINE:

- Yanmar 4TNV98C engine for reliable power.

- Accessible engine compartment under the rear hood.

- Glow plug starting aid for cold starts.

- Dry-type air cleaner with a restriction indicator to maintain clean air intake.

ELECTRICAL:

- 12-volt electrical starting system ensures reliable ignition.

- Heavy-duty battery for prolonged life and performance.

- Battery Master Switch for enhanced electrical control.

- Key Start system for ease of use.

- Anti-theft engine starting passwords for added security.

- Front and rear working lights for improved visibility.

- 12 V power outlet for charging and powering devices.

- Auto-idle feature with an on/off switch saves fuel and reduces noise.

- Horn for safety and communication on job sites.

- Pre-wired for Telematics, ready for connectivity and fleet management.

HYDRAULICS:

- Auxiliary hydraulics with independent single and bi-directional flow and plumbing to the arm for various attachments.

- Large hydraulic oil cooler to maintain optimal operating temperatures.

- Electronic pattern changer in the cab is used for easy configuration control.

- Cylinder rod protection covers for the backfill blade and boom to prevent damage.

TRACK DRIVE:

- Rubber tracks for reduced ground damage and enhanced traction.

- Automatic 2-speed travel for efficient movement across job sites.

- Fully hydrostatic drive system for smooth, responsive control.

- Sealed and lubricated track rollers for durability and reduced maintenance.

- Grease-type track tension adjustment for easy maintenance.

OPERATOR ENVIRONMENT:

- Enclosed cab with heat and air conditioning for all-weather comfort.

- Compliant with ISO 6396:2008 sound pressure level LpA=76dB(A) for a quieter operation.

- Pilot-operated hand controls and foot pedals are used for precise machine control.

- Adjustable seat with a seat belt and seat heater for operator comfort and safety.

- Armrests, 12V socket, 5.7 in color LCD display, cup holder, and cell phone holder for convenience.

- Bluetooth radio with USB input, two speakers, and remote control for entertainment and connectivity.

- Display includes a comprehensive array of warning lamps and gauges for monitoring machine status.

UPPER STRUCTURE:

- Conventional radius tail swing for improved maneuverability in tight spaces.

- Standard arm length of 5 ft 3 in (1.6 m) for versatile operation.

- Heavy counterweight, 220 lb (100 kg) heavier than standard, for increased stability.

- Bucket linkage with lifting hook for versatile attachment use.

- Thumb bracket for easy attachment of hydraulic thumbs.

OTHER:

- Swing boom feature allows 80° left and 50° right movement for flexibility in tight spaces.

- Hydraulic backfill blade for efficient backfilling and grading tasks.

CX57C Optional Equipment

OPERATOR ENVIRONMENT:

- Rearview Camera: This camera enhances the operator’s safety and visibility by providing a clear view of the area behind the machine.

- Travel Alarm: Increases job site safety by alerting others when the excavator is in motion.

TRACK OPTIONS:

- Steel Tracks: They are available in widths of 1 ft 4 in (400 mm) and 1 ft 6 in (450 mm), offering enhanced durability and traction.

- Steel Tracks with Bolt-On Rubber Pads: These track systems are 1 ft 4 in (400 mm) wide and combine the durability of steel tracks with the flexibility and reduced surface damage of rubber pads.

- Roadliner Tracks: Steel chain with rubber grousers/shoes in 1 ft 4 in (400 mm) width, ideal for balancing traction and surface protection.

- Rubber Belt Tracks: 1 ft 4 in (400 mm) width, providing excellent traction and minimal ground disturbance.

- Track Guides for Steel Tracks and Steel Tracks with Bolt-On Rubber Track Pads: Available in full or 3-piece options, these guides help maintain track alignment and enhance stability.

OTHER:

- Optional Long Arm: 6 ft 3 in (1.9 m) for extended reach and depth in digging and trenching applications.

- Hydraulic Quick Coupler Provision: Allows quick and easy attachment changes, enhancing versatility and productivity.

- Klac Coupler: A mechanical quick coupler system for easy and secure attachment changes.

- Mechanical Coupler: Offers a simple and effective solution for changing attachments without hydraulic intervention.

- Hydraulic Hammer: A robust attachment for breaking through concrete, asphalt, and rock.

- Beacon: A safety feature that provides a visible alert to enhance job site safety.

- 2nd Auxiliary Circuit: Offers additional hydraulic power for running complex attachments.

- Hydraulic Coupler: Enables quick and easy attachment changes with the convenience of hydraulic operation.

CX57C Warranty

Base & Extended Warranty Coverage

- 2yr/3,000 hours Full machine limited warranty

Purchased Protection

Purchased Protection Plan is an extension of the factory base and extended coverage is available at an additional cost. Your CASE dealer can help you determine the plan that fits your needs.

Please see your CASE dealer for limitations, exclusions, and confirmation of policies in effect. The CASE Warranty remains in effect during the Warranty Period if the owner performs the required maintenance at the recommended intervals outlined in the product’s operator’s manual and the unit is operated within its rated capacity. Genuine CASE service parts or CASE-approved service parts that meet CASE specifications must be used for maintenance and repairs.